|

Shandong Chuanyi Water Treatment Equipment Co.,ltd

|

sodium ion exchange for boiler /water softener

| Qty (Set/Sets) | Unit Price (1350.0~1500.0 USD) |

| 1 - 4 | 1500 |

| 5 - 9 | 1400 |

| 10 + | 1350 |

| Trade Term: | FOB,CFR,CIF |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

full automatic controller for easy opearte and save manual work

one work one standby type can work 24 giyrs a day

low salt consumption

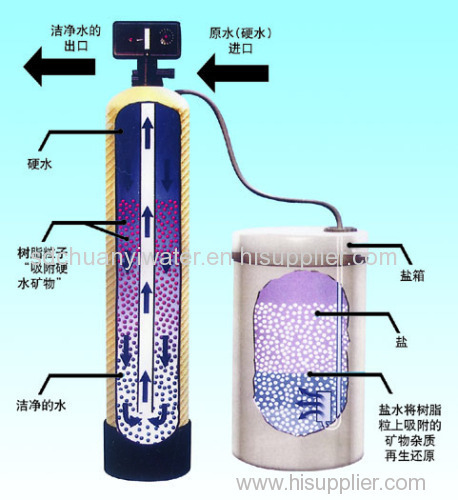

When raw water with rigid ion passing resin in the exchanging cylinder, Ca2+, Mg2+ in water is exchanged and absorbed by Na+ in resin, wiping off Ca2+, Mg2+ and carbonate or non carbonate rigidity, is called softened water.

The resin must be regenerated after absorbing some Ca2+ Mg2+, regeneration is washing resin layer using brine in salt box. Na+ in salt water exchange the rigid ion of resin into water, then discharged with regeneration liquid off the cylinder. Recovering exchanging capacity, and continuously softening water.

Type: 1 double full automatic water softening equipment(one in production, one for standby)

2 single full automatic water softening equipment

3 fully automatic with multiple valve water softening group

Application range

Widely used in various industrial and civil softened water preparation, such as boiler water, make-up water in heating air conditioning systems, textile printing and dyeing, paper making, clothes washing, bathing, food processing, high quality water and other fields. Disposing flow rate is from 0.3 to several scores of tons per hour.

Characteristics:

Easy management: Professional knowledge is not required for user. Equipment is really belong to "full automation"; All management is regularly salt-adding

Continuous outflow: Double tanks system with one for production and one for preparation, continuously supply water in 24 hours.

Controllable flow rate: Ensure the operation to be economical and reliable.

Up-flow regeneration: Regenerative adopts counter-current process, and regenerating and washing with softened water, achieving low salt consumption and high quality water out flow.

Simple maintenance: Low malfunction rate.

Note: KFR flow automatic soften water equipment technical parameters; Raw water hardness is 3-10mmoi/l, such as raw water hardness higher than 10mmoi/; , changing to a large model or using second grade softening.